FULL-SERVICE-PRODUCTION

Gaslock manufacturing draws on the very latest technologies – just as in mass production. Quality management is certified according to cutting-edge standards (DIN ISO 9001:2015), attaching particular importance to the most stringent environmental protection measures. To meet customer needs, all products are dispatched in transport packaging which allows low-cost interim storage. In order to provide optimum customer service we even take on development and production of the end packaging so as to be able to supply ready-for-sale products on a just-in-time basis.

All products undergo final assembly on our own process-optimized assembly lines and subjected to a 100 % inspection. No product leaves our company if it has not undergone multiple testing for function, fitting accuracy and perfect visual appearance.

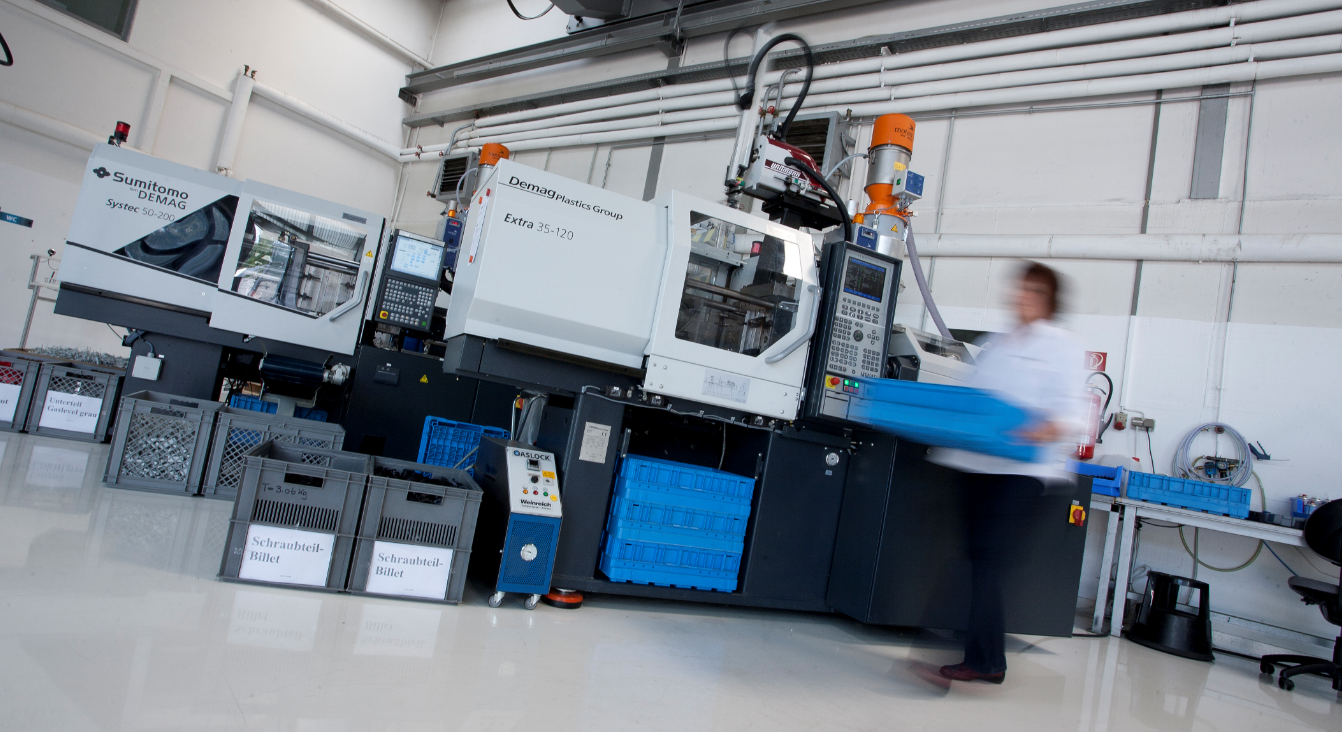

Components made of synthetics are used where the focus is on shape, function and material-specific requirements. Mold design is always optimized for set-up time and cost. Here again, not only functionality is crucial but also the very highest visual and tactile standards.

Cart is empty

Cart is empty